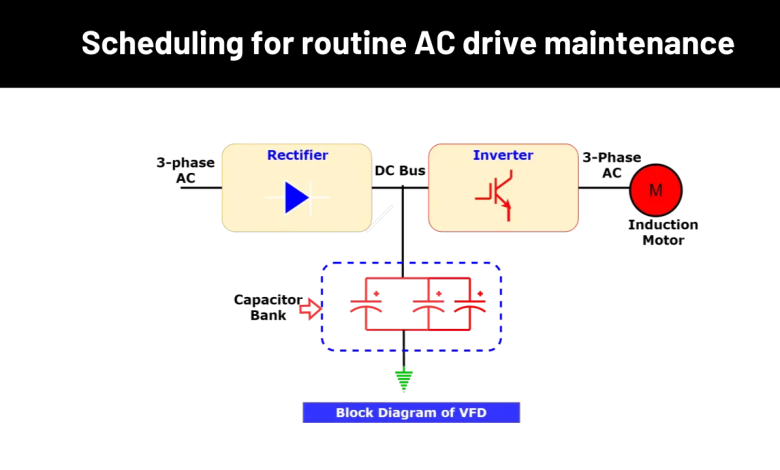

Scheduling for routine AC drive maintenance

Scheduling periodic maintenance is crucial to ensuring the maximum performance and lifetime of an AC drive.

1. Consult the manufacturer’s maintenance guidelines:

Referring to the manufacturer’s maintenance guidelines is an essential part of effectively maintaining an AC drive. These instructions include detailed information on how to maintain and repair the AC drive.

The manufacturer’s instructions usually provide details on recommended maintenance intervals, normal maintenance tasks, cleaning and inspection procedures, and troubleshooting steps for common issues.

The manufacturer of the AC drive will often recommend maintenance schedules and procedures. Follow directions exactly to ensure that you are correctly maintaining the drive.

Read: Rockwell Automation 22F-A1P6N103 PowerFlex 4M AC Drive

Create a maintenance checklist:

Make a list of the routine maintenance tasks that must be completed. Maintaining the operational environment, checking electrical connections, cleaning the enclosure, and testing the cooling system may be included in this.

Check the cooling system:

- Check the temperature

- Inspect the fans

- Check the filters

- Check the vents

Inspect electrical connections:

- Power off the AC drive

- Visually inspect the connections

- Check terminal blocks and connectors

- Verify wiring connections

Monitor the operating environment:

- Check the temperature

- Check the humidity

- Monitor vibration

- Check for dust and debris

- Monitor the power supply

2. Establish a maintenance schedule

Decide how frequently each maintenance operation has to be carried out and create a schedule to ensure that everything is finished on time. This might be weekly, monthly, or annually, depending on the specific work.

Allen Bradley PowerFlex AC drives

To construct an AC drive maintenance program, follow these general procedures:

- Consult the manufacturer’s guidelines and suggested maintenance regimen.

- Examine the operating conditions of the AC drive, taking into account the workload, environmental factors, and usage patterns.

- Make a decision on the frequency and size of maintenance chores based on your evaluation and the manufacturer’s guidelines.

- Create a maintenance checklist outlining all the steps that need to be completed during each visit.

- Assign maintenance responsibilities to competent staff members.

- Make a schedule for maintenance visits based on the frequency and workload of the AC drive.

- Record maintenance activities and results for later analysis and reference.

It is essential to follow the manufacturer’s instructions and seek the assistance of knowledgeable professionals to develop a maintenance schedule that is appropriate for your specific AC drive and operating conditions.

3. Assign responsibility:

Select the person in charge of each duty and make sure they have the relevant training.Assigning responsibilities is essential for ensuring that maintenance is completed accurately and on schedule. Each maintenance-related duty should have a designated person in charge, and you should make sure they have the right equipment and training. This may mean giving the job to an internal maintenance team or contracting with an outside service provider.

4. Keep records:

Make careful to document any AC drive maintenance, including the time it was performed and the person who conducted it.

Keeping records is a vital part of AC drive maintenance. It helps maintain track of the history of the AC drive and could be useful in identifying patterns or trends in issues that could emerge over time.

- maintenance plans and checklists

- used components and new parts history; history of servicing and repairs

- Electrical and mechanical system schematics and illustrations

- Data on energy utilisation from calibration and testing results

- Error codes and fault histories

By taking note of these recommendations, you can establish a regular maintenance schedule that will promote the longevity and optimal operation of your AC drive. Establish a regular maintenance programme for the AC drive, which should include cleaning, inspection, and testing to make sure it is working as efficiently as possible and lower the likelihood of unscheduled downtime.

Asteam Techno Solutions Pvt Ltd will assist you with arranging routine maintenance for the Rockwell Automation variable frequency drives. There is no breakdown or issue we cannot repair thanks to our stock of excess and outdated spare parts and our staff of skilled professionals. Receive assistance for all equipment types, including PLCs, HMIs, and other automation components, as well as AC, DC, and servo drives.