Introduction to Wire Mesh Manufacturing

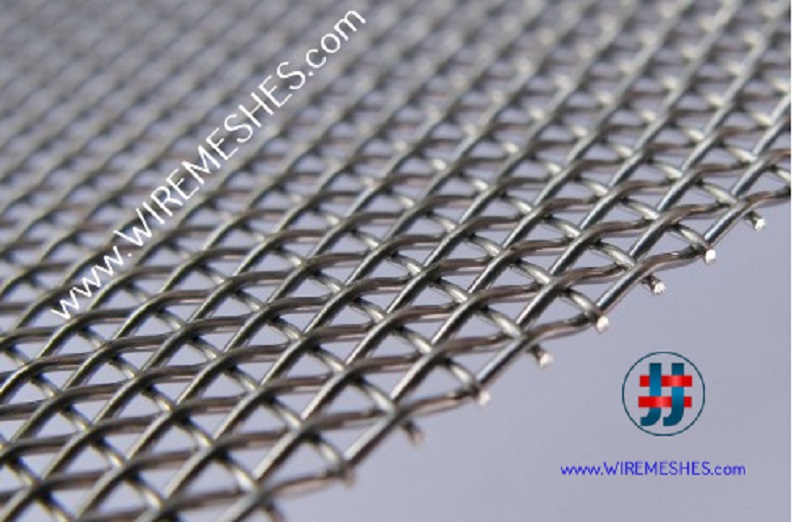

Wire mesh, a versatile product with numerous applications across various industries, has been a vital material for generations. Its primary purpose remains to sieve, separate, protect, and reinforce. The need for high-quality wire mesh has led to the growth of numerous manufacturers across the globe. Among the standout names in this industry are Jeetmull Jaichandlall (P) Ltd, PB Wire Mesh Manufacturers, GI Wire Mesh Manufacturers, and the pioneers in Welded Mesh Manufacturers. This article will dive deep into understanding these industry giants and what sets them apart in the world of wire mesh manufacturing.

Our Tradition Meets Modernity

Founded on the bedrock of experience and innovation, We have etched its name as a top-tier manufacturer. The firm has consistently delivered exceptional quality wire meshes, ensuring that industries reliant on this product never compromise on quality.

Their production techniques seamlessly merge traditional methods with state-of-the-art technology, making their products robust and fit for multiple applications. This integration of time-tested techniques and innovative technology has been a signature of their manufacturing process.

PB Wire Mesh Manufacturers: The Benchmark of Consistency

Another stalwart in this realm, PB Wire Mesh Manufacturers has carved a niche for themselves with their unwavering commitment to excellence. The secret behind their consistent product quality lies in their rigorous quality control measures and an in-depth understanding of the intricacies of wire mesh production.

Their offerings cater to a vast range of industries, from agriculture to construction, proving their versatility and understanding of varying industry needs. When you think of consistency and reliability, PB Wire Mesh is often the first name that springs to mind.

Welded Mesh Manufacturers: Crafting Strength and Durability

Welded wire mesh is a special category that requires precision and an acute understanding of its application areas. Welded Mesh Manufacturers lead the charge in this segment, offering meshes that boast superior strength and unparalleled durability.

Their manufacturing process is refined, ensuring each weld’s precision and the mesh’s overall integrity. This meticulous process ensures that the final product can withstand significant stress, making it a top choice for industries where strength is a non-negotiable criterion.

Applications of Wire Mesh Across Industries

Wire mesh is not just a product but a solution to numerous challenges across various sectors. Here are some key applications:

- Construction: For reinforcement in concrete structures and to fence areas for safety.

- Agriculture: As barriers to keep pests away or to build enclosures.

- Mining: To segregate materials based on size and consistency.

- Manufacturing: In the filtration process separate unwanted particles.

Choosing the Right Wire Mesh Manufacturer

While there are numerous players in the market, selecting the right manufacturer is crucial for an industry’s success. Factors to consider include:

- Quality Assurance: A consistent track record of delivering high-quality products.

- Technological Advancements: Usage of modern machinery and techniques.

- Client Testimonials: Feedback from previous customers can provide valuable insights.

- Customization Options: The ability to cater to specific requirements.

Conclusion

In the intricate world of wire mesh manufacturers, the names mentioned stand tall due to their relentless pursuit of perfection. Jeetmull Jaichandlall (P) Ltd, PB Wire Mesh Manufacturers, and Welded Mesh Manufacturers are more than just manufacturers; they are trendsetters leading the charge in bringing top-notch products to industries worldwide.